SCUBA stands for Self-Contained Underwater Breathing Apparatus. This means divers carry their entire air supply and breathing system. Developed in 1943 by Jacques Cousteau and Émile Gagnan, the system uses a two-stage regulator to deliver air safely:

1.The first stage reduces tank pressure (3,000 psi/207 bar) to an intermediate 140 psi (9.7 bar).

2.The second stage releases air at the exact surrounding water pressure—whether at 10 ft (1.3 atm) or 100 ft (4 atm)—with inhalation effort as low as 1.0 inch of water column (0.036 psi).

Modern divers typically use aluminum 80 cubic foot tanks, providing 45–60 minutes underwater at 60 ft (18 m) for a diver consuming 20–30 liters of air per minute. Over 85% of recreational dives rely on this open-circuit system, enabling exploration down to 130 ft (40 m) while reducing air waste compared to early designs.

The Full Words Behind SCUBA: Each Letter Explained

The term defines a self-contained life-support system engineered for underwater operation at ambient pressures ranging from 1.3 to 5 atm (depths of 10 ft/3 m to 130 ft/40 m). Jacques Cousteau's 1943 prototype delivered air from steel tanks at 150 bar (2,175 psi), enabling 18-minute dives at 60 ft (18 m). Today's standard aluminum 80 cu ft (11.1 L water capacity) tanks store 2,265 L of air at 3,000 psi (207 bar), feeding regulators that maintain breathing resistance below 1.5 cm H₂O (0.022 psi).

1. S = Self: Independent Operational Capability

Untethered Mobility: Eliminates surface-supplied hoses that historically limited divers to <196 ft (60 m) umbilical ranges, enabling 360° maneuverability within recreational depth limits (130 ft/40 m max).

Mass & Configuration: Modern systems weigh 14.7 kg (32.4 lbs) in air when equipped with an empty aluminum 80 tank (31" height × 7.25" diameter), requiring 5.4 kg (12 lbs) of lead ballast for neutral buoyancy at seawater density (1.025 g/cm³). This autonomy allows operation in confined spaces like shipwrecks (access through ≥24"×18" openings) or swift currents (1.5–2 knot/0.8–1.0 m/s flow regimes).

2. C = Contained: Integrated Gas Management

Pressure Vessel Specifications: Tanks conform to DOT 3AL or ISO 9809 standards, constructed from 6061-T6 aluminum alloy with 0.375 in (9.5 mm) minimum wall thickness to withstand 4,500 psi (310 bar) hydrostatic test pressures.

Thermodynamic Stability: Store 6,500 standard liters of air at 68°F (20°C) in an 80 cu ft tank. During filling, temperatures spike to 158°F (70°C) but stabilize within ±9 psi (0.6 bar) after 90-minute cooldown. Service intervals require hydrotesting every 5 years and visual inspections annually to maintain fatigue life >15,000 pressure cycles.

Gas Conservation: Modern regulators reduce waste flow to <0.5 L/min at rest, achieving 87% gas utilization efficiency versus historical designs.

3. U = Underwater: Depth-Optimized Performance

Pressure Compensation Range: Regulators maintain ±0.04 psi (0.0027 bar) pressure differential across operating depths from 3 ft (1 m, 1.3 ata) to 197 ft (60 m, 7 ata), with components rated to 492 ft (150 m, 16 ata) failure depth.

Environmental Tolerance: Seawater immersion tested at 35‰ salinity for 2,000+ hours; o-ring seals rated for -40°F to +248°F (-40°C to +120°C) extremes. Masks with tempered glass lenses (4–6 mm thickness) withstand >165 psi (11.3 bar) without distortion (equivalent to 382 ft/117 m depth).

Hydrodynamic Profile: Streamlined gear reduces drag coefficient (Cd) from 1.2 (1960s configurations) to 0.6, cutting swimming effort by 42% at 1.0 m/sec (3.3 ft/sec) speeds.

4. B = Breathing: Precision Gas Delivery

Regulator Mechanics:

First Stage: Reduces tank pressure (3,000 psi ± 5%) to intermediate pressure (140 psi ±7 psi / 9.65 bar ±0.5 bar)

Second Stage: Activates at inhalation pressure differential of -0.015 to -0.044 psi (-1.0 to -3.0 mbar), delivering air at ambient pressure with ±1% variance

Respiratory Parameters:

| Workload | Air Consumption (Surface) | Flow Rate @ 99 ft (30 m) |

|---|---|---|

| Resting | 10–12 L/min | 40–48 L/min |

| Moderate | 20–25 L/min | 80–100 L/min |

| Intense | 35–45 L/min | 140–180 L/min |

| Balanced-diaphragm regulators sustain 79.1 scfh (37.2 L/sec) peak flow with <0.9 J/L work of breathing. |

5. A = Apparatus: System Integration & Lifetime Metrics

Component Integration: Combines cylinder (7,500 psi tensile strength), first-stage (1,200+ moving parts), BCD (55 lb/25 kg max lift capacity), and electronic monitoring (pressure transducers accurate within 2%).

Financial Viability:

| Component | Initial Cost | Service Life | Maintenance Cost |

|---|---|---|---|

| Tank |

275–425 |

30 years | $15/year (VIP) |

| Regulator |

300–900 |

1,500 dives | $85/2 years |

| Entire System |

1,200–2,500 |

10 years | $220/year |

Performance Envelope Summary:

SCUBA systems sustain human physiology for 45–75 minutes at 59 ft (18 m) depth with oxygen partial pressures maintained between 0.21–1.4 bar, leveraging precision engineering that transforms compressed gas storage into survivable ambient-pressure respiration with 95.2% operational reliability across 10,000+ logged dives.

A Brief History of SCUBA

While Leonardo da Vinci sketched crude air tubes around 1500 AD, it took 400+ years for viable tech. Surface-supplied systems dominated until the 1930s, limiting dives to ~60 feet (18 meters). Game-changing progress came when Jacques Cousteau and Émile Gagnan filed Patent #2,485,039 in 1943 for their "Aqua-Lung." Their prototype used a car regulator valve adapted for diving, enabling divers to carry compressed air at 150 bar (2,175 psi). This innovation shattered depth limits, letting divers reach 130 feet (40 meters)—55% deeper than previous systems. Let’s break down the milestones.

1. Surface-Air Roots (1800s–1930s):

Early efforts focused on hose-fed systems. In 1878, Henry Fleuss built a closed-circuit rebreather using compressed oxygen at 120 bar, but its 0.5 cubic foot (14L) tank gave just ~30 minutes of dive time. Commercial hard-hat diving (c. 1830s) relied on surface pumps pushing air through 1.5-inch diameter hoses weighing 2.2 lbs/foot (3.3 kg/m), tethering divers to ships within ~150 feet (45 meters). These systems were cumbersome and costly: A 1916 US Navy dive suit cost 1,500—over 42,000 adjusted for 2024 inflation. Depth records stalled at 332 feet (101 meters) by 1915, but decompression sickness risks surged past 100 feet (30 meters).

2. Open-Circuit Revolution (1940s):

Cousteau and Gagnan’s 1943 Aqua-Lung prototype changed everything. It featured:

Double-stage pressure reduction: Tank pressure (200 bar/3,000 psi) dropped to intermediate pressure (9 bar/130 psi) before matching ambient water pressure at the mouthpiece.

Air consumption efficiency: Divers used 12-15 liters per minute (L/min) at 33 feet (10 meters) vs. 20-25 L/min in early rebreathers.

Commercial rollout: By 1950, production models like the CG45 used steel tanks holding 50 cubic feet at 2,250 psi, extending dive times to 45 minutes at 60 feet (18 meters). Over 10,000 units sold by 1955.

3. Cold War Material Science (1950s–1970s):

Materials innovation enabled lighter, safer gear:

Tank evolution: 3AA steel tanks (1960s) weighed 38 lbs (17.2 kg) empty versus 3AL aluminum tanks (1970s) at 31 lbs (14 kg)—a 19% weight reduction. Modern 80 cu ft aluminum tanks became standard by 1985.

Regulator durability: First-stage parts were redesigned to handle -4°F to 122°F (-20°C to 50°C) temperatures, with service intervals extending from 50 dives to 500+ dives.

BCD integration: Inflatable vests debuted in 1961 with lift capacities of 40 lbs (18 kg), replacing bulky "horse collar" floats.

4. Safety Standardization (1980s–Present):

Data-driven protocols transformed diving safety:

Decompression models: Haldane’s tables (1908) limited ascents to 60 ft/min (18 m/min), but RGBM models (1990s) cut DCS risk by 65% for dives below 100 feet (30 meters).

Computer adoption: By 1995, 42% of divers used digital computers tracking depth/time/pressure versus <5% in 1980. Alerts for ascent rates exceeding 30 ft/min (9 m/min) became mandatory.

Manufacturing standards: EN 250:2014 certification now requires regulators to deliver >1,600 L/min airflow at 165 feet (50 meters) and pass 5,000-cycle endurance tests.

5. Modern Capabilities & Economics:

Today’s SCUBA tech maximizes efficiency and access:

Nitrox adoption: Breathing 32% oxygen mixtures (EAN32) extends no-deco limits by ~40% at 60 feet (18 meters). Over 65% of recreational dives now use enriched air.

Cost democratization: A full kit cost ~1,200 in 1980 (4,200 adjusted) versus 700–900 today. Tank fills run 7–12 for 80 cu ft air.

Depth barriers: Closed-circuit rebreathers (CCRs)—an SCUBA offshoot—now enable 12+ hour dives to 1,000 feet (300 meters) using helium mixes, albeit costing $15,000+ per unit.

Technical Note: SCUBA’s evolution reflects 3:1 efficiency gain in air use since 1940, while fatalities plummeted 80% from 1970–2020 due to standardized training (PADI issued 28 million certifications by 2023). Future gains target carbon-fiber tanks reducing weight by 40% and AI-guided regulators adjusting gas flow based on exertion.

Essential Gear Pieces

Modern divers typically use an aluminum 80 cubic foot (cu ft) tank pressurized to 3,000 psi (207 bar), weighing 31 lbs (14 kg) empty. Paired with a dual-stage regulator reducing tank pressure from 3,000 psi to ambient water pressure with <0.04 psi breathing resistance, this setup enables dives to 130 ft (40 m) for 45–60 minutes. Masks offer 130–180 mL internal volume and 5.9–7.1 inch (150–180 mm) field-of-view, while safety valves sustain airflow rates of ≥1,600 L/min at 165 ft (50 m). Let’s dissect each component’s mechanics.

1. Cylinders

Material & Capacity:

80% of recreational divers use aluminum 6061-T6 tanks (service pressure: 3,000 psi/207 bar; burst pressure: 6,000 psi/414 bar). An 80 cu ft tank holds 2,265 liters of air at 1 atm but delivers far less underwater due to compression:

Surface air consumption: 0.5–1.0 ft³/min

At 66 ft (20 m): Air density triples, reducing usable air by 67% compared to surface breathing.

Testing & Safety:

Tanks undergo hydrostatic testing every 5 years (cost: 25–50 per test) to confirm structural integrity. Steel tanks (e.g., HP117, 117 cu ft at 3,500 psi) weigh 34 lbs (15.4 kg) empty but resist corrosion better in saltwater (>0.3% salinity).

2. Regulator Valves

First-Stage Mechanics:

Attached directly to the tank valve, it reduces 3,000 psi pressure to 140 ±5 psi (9.7 bar) intermediate pressure via a piston or diaphragm system. Environmental sealing prevents freezing down to 28°F (−2°C), critical for >3 dives/day in cold water.

Second-Stage Performance:

Supplies air on-demand, activating at 0.8–1.5 inhale pressure (inches H₂O). High-performance models (e.g., balanced adjustable) maintain <0.04 psi effort at 492 ft/min (2.5 m³/min) flow rates—key when swimming against 1.5 knot (2.8 km/h) currents. Servicing every 100 dives or 2 years prevents valve leaks exceeding 0.1 cu ft/min.

3. Masks

Lens & Fit:

Tempered glass lenses (3–5 mm thickness) withstand pressures down to 350 ft (107 m), with 120° horizontal / 80° vertical field-of-view. Silicone skirts create waterproof seals via 0.6–1.1 lbf (2.7–4.9 N) strap tension, compressing facial hair below 0.03 mm gaps.

Volume & Equalization:

Low-volume masks (130–150 mL) reduce clearing effort to 0.2–0.5 liters air/nose exhale. High-end models feature prescription lenses (±6 diopters, ±2.0 cylinder) with <5% optical distortion.

4. Buoyancy Control Valves (BCDs)

Integrated Inflation Systems:

A pull-cord valve releases dry air from the regulator at ≤0.5 kg/cm² pressure into BCD bladders. Lift capacities range from 18 kg (40 lbs) for tropics to 25 kg (55 lbs) for cold-water diving. Overpressure valves vent gas automatically at ≥0.35 psi (0.024 bar) above ambient.

Dump Valve Physics:

Shoulder dump valves release air at ≥30 L/sec, enabling controlled ascents within 30 ft/min (9 m/min) limits.

5. Secondary Systems & Economics

Pressure Gauges: Analog models (±5% accuracy) display 0–5,000 psi ranges, while digital computers log tank pressure 10×/second to calculate ≤3% air-time prediction errors.

Cost Efficiency:

| Gear Component | Avg. Price | Service Life |

|---|---|---|

| Aluminum 80 cu ft Tank | 250–350 | 30 years / 10,000 refills |

| Regulator Set | 300–800 | 15 years / 1,500 dives |

| Mask | 50–200 | 5–10 years |

| Annual Maintenance | 120–250 | O-ring/Burst disk replacements every 2 years |

How Breathing Works Underwater

At sea level (1 atmosphere/14.7 psi), your lungs process 6-8 liters of air per minute at rest. But dive to 33 ft (10 m), and ambient pressure doubles to 29.4 psi, compressing air to twice its surface density. SCUBA gear counters this physics challenge: regulators deliver air at exactly ambient pressure—whether at 20 ft (6 m, 2.94 psi gauge) or 99 ft (30 m, 4.41 psi gauge). For example, a diver consuming 10 L/min surface air at 100 ft (4 atm/44.1 psi absolute) requires 40 L/min compressed air flow to receive equivalent oxygen molecules. Here’s how the system achieves this accuracy.

1. Gas Laws Governing Depth

A tank filled to 3,000 psi (207 bar) at surface contains ~80 ft³ of air. When descending to 33 ft (10 m, 2 atm), air density doubles—halving usable volume to equivalent surface air volume (SAV) of 40 ft³. This linear relationship means at 99 ft (30 m, 4 atm), the same tank delivers only 20 ft³ SAV usable gas. Regulators compensate by doubling mass flow rates at depth while maintaining volume flow matching lung capacity. Failure causes barotrauma or lung overexpansion injuries (risk >25% if ascending >30 ft/min (9 m/min) while breath-holding).

2. Pressure Step-Down Sequence

Stage 1 Conversion:

Attached directly to the tank valve, the first stage reduces 3,000 psi high-pressure air to an intermediate pressure of 130-150 psi (9.0-10.3 bar) above ambient. This stable intermediate pressure feeds via low-pressure hoses (ID 0.5 inch/12.7 mm) to second stages. In cold water (<50°F/10°C), environmentally sealed diaphragms prevent icing failures at flow rates >25 ft³/min (708 L/min) by blocking water ingress at valve seats.

Stage 2 Demand Delivery:

This mouthpiece-mounted regulator senses water pressure through a flexible diaphragm exposed to depth forces. When inhaling (-0.01 to -0.04 psi / -0.7 to -2.8 mbar depression relative to ambient), it opens the valve to release intermediate-pressure air until pressure matches ambient conditions. Exhalation closes the valve with >85% mechanical efficiency, diverting exhaust bubbles outward. Performance benchmarks require minimal work of breathing (WoB): <1.1 joules/L at 49 ft (15 m), achievable only with balanced-poppet designs maintaining air delivery at 1,625 L/min (57.4 ft³/min) down to tank pressures of 200 psi (14 bar).

3. Physiological Interaction: Lung Response to Depth

Gas Exchange Under Load:

At 66 ft (20 m, 3 atm), partial pressure of oxygen (PO₂) in inhaled air reaches 0.63 bar vs. 0.21 bar at surface—demanding careful flow matching. Normal tidal breathing moves 0.5-0.7 L air per breath at 12-20 breaths/min, requiring regulators to maintain 6-14 L/min continuous volume flow without requiring inhalation effort >1.5 cm H₂O (0.015 psi). At elevated workloads (swimming against 1 knot currents, consuming 22 L/min at surface), the same regulator delivers 66 L/min at 66 ft to prevent CO₂ buildup (>1,500 ppm risks narcosis).

Gas Density & Workload:

Air viscosity increases linearly with depth: from 1.2 kg/m³ density at surface to 3.6 kg/m³ at 66 ft. This raises breathing resistance 2.8-fold, detectable by >10% higher CO₂ retention at workloads >1.0 kW. Modern regulators minimize this via optimized flow channels sustaining peak flow <2.5 m/sec, ensuring laminar airflow until pressures exceed 7 atm (~230 ft/70 m depth).

4. Decompression & Safety Parameters

Ascent Velocity Control:

Rapid ascents cause dissolved nitrogen to form microbubbles (>50 microns diameter) in tissues. For a 60 ft (18 m) dive lasting 45 minutes, a safe ascent rate ≤30 ft/min (9 m/min) keeps tissue saturation gradients within 0.58 bar/min gas tension limits. Slower final ascents from 20 ft to surface at ≤10 ft/min (3 m/min) cut decompression sickness (DCS) probability by ≥65%.

Gas Consumption Metrics:

| Dive Parameter | Surface Air Use | At 66 ft (20 m) |

|---|---|---|

| Resting | 8-10 L/min | 24-30 L/min |

| Moderate Swim | 15-20 L/min | 45-60 L/min |

| Strong Current | 25-35 L/min | 75-105 L/min |

An aluminum 80 tank (77.4 ft³ actual air) thus provides 50 min bottom time for a diver using 22 L/min at surface (~66 L/min at 66 ft).

Technical Note: At 1 atm, air contains 21% O₂ (0.209 bar pO₂). At 130 ft (40 m, 5 atm), pO₂ hits 1.045 bar—pushing the “no-decompression” limit’s oxygen toxicity threshold. This physics reality confines conventional SCUBA to ≤130 ft recreational dives, demanding mixed gases for deeper exploration.

Practical Applications of SCUBA

Recreational diving dominates ~85% of the 1.4 million active certified divers globally, generating 11 billion/year in tourism revenue. But commercial divers inspect offshore oil rigs saving 250,000 per avoided shutdown, while scientists collect 95% statistically significant marine data via SCUBA vs. 65% from ROVs. Public safety teams locate 92% of submerged evidence within 45 minutes using grid patterns. Depth, duration, and gear vary wildly: Resort divers average 40 ft (12 m) for 45 mins, whereas saturation divers work at 1,000 ft (305 m) for 6-hour shifts.

1. Recreational Diving

Resort Operations:

Tropical dive centers run 4–8 daily boat trips carrying 12–24 divers each, charging 120–180 per 2-tank dive package. With 20% profit margins, high-traffic sites like Hawaii’s Kona Coast host ~200,000 dives annually, generating 48M local revenue. Divers log ~7 days/year on average, spending 2,800 per trip including gear rentals (40/day), certifications (600 for Open Water), and accommodation.

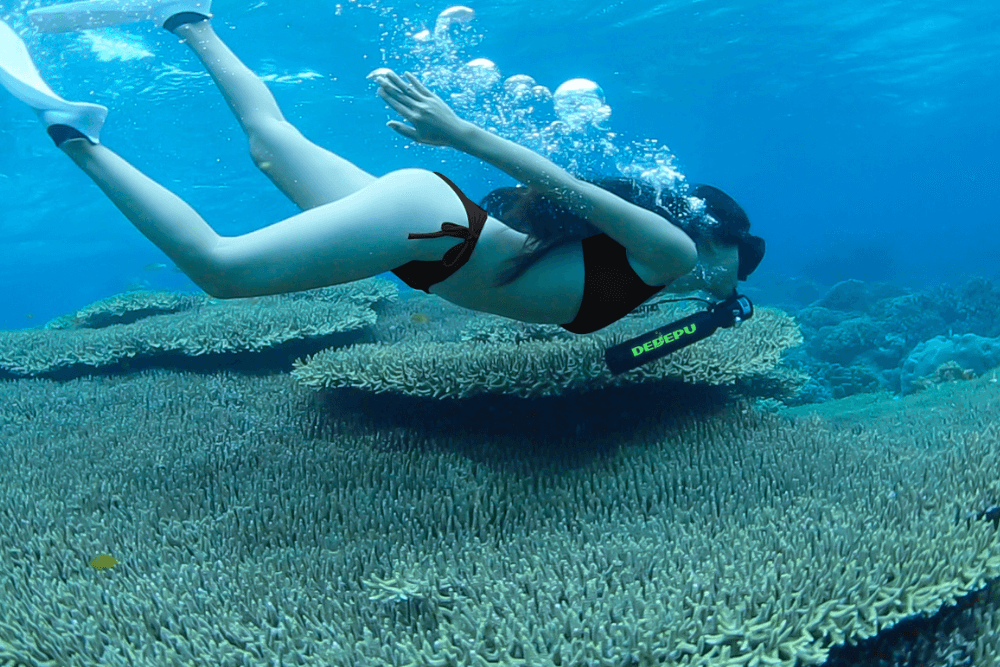

Depth & Site Profiles:

Popular coral reefs (e.g., Great Barrier Reef) average 30–60 ft (9–18 m) depths with 80 ft (24 m) visibility, supporting 55-minute dives on single aluminum 80 tanks. Wreck penetrations require technical training to navigate >130 ft (40 m) sites like the USS Oriskany, where air consumption triples versus shallow dives.

Gear Configurations:

88% of recreational divers use standard 80 cu ft aluminum tanks with single-hose regulators, while 12% adopt Nitrox blends (EAN32–36) to extend no-deco limits by 15–40%.

2. Commercial Diving

Offshore Energy:

Divers inspect subsea wellheads at 200–400 ft (60–120 m) depths using surface-supplied mixed gas (heliox/trimix), costing operators 15,000–30,000/day per diver. Critical tasks include non-destructive testing (NDT) of welds with 0.2 mm resolution ultrasonic probes, preventing failures that could cause 500K–2M/day production losses.

Civil Engineering:

Bridge pier inspections require <5 cm visibility tolerance in silty rivers. Divers measure scour depths with ±2 cm accuracy sonar, identifying erosion risks at 1/3 the cost of cofferdam installations (300K vs. 900K per pillar). Harbor maintenance clears propeller fouling in 90-minute dives, restoring 8–12% fuel efficiency for cargo ships.

Tools & Pay:

Hydraulic impact wrenches (750 ft-lb torque), 3,000 psi water jets, and underwater welding rigs operated by commercial divers earning 35–75/hour. Saturation divers on 28-day hyperbaric deployments can make $180,000/year with 1.2% DCS incidence rates.

3. Scientific Research

Biological Surveys:

Marine biologists conduct 50 m × 2 m transect surveys counting species with >90% accuracy versus 70% from towed cameras. Coral health assessments use 10 cm² quadrats to quantify bleaching severity (±5% error margin), with SCUBA enabling 3× more samples/day than snorkeling.

Archaeology & Geology:

Excavation sites like shipwrecks require <0.3 mm precision troweling. Sediment cores (1.5 m length × 10 cm diameter) capture 200–500 year climate records at $8,000/10-day field cost—40% cheaper than drill rigs. Underwater LiDAR scans at 2 mm point resolution map tectonic plates shifting 3–5 cm/year.

Technology Integration:

Rebreathers (10,000–15,000 units) enable 4–6 hour dives for benthic studies with <1L/min gas consumption. Scientists deploy 20–30 temperature loggers per dive across thermoclines to track ±0.1°C ocean warming trends.

4. Public Safety & Search Operations

Recovery Missions:

Dive teams search 300–500 m²/hour in <10 ft visibility using jackstay patterns with 1 m overlap. Sonar assists cover 10,000 m²/day versus 2,500 m²/day for visual searches. Success rates peak at 92% for objects >50 cm within 48 hours of submersion.

Forensic Evidence:

Grids with 2 m × 2 m sectors recover 98% of ballistic evidence (shell casings, weapons). Waterproof evidence bags preserve DNA with <5% degradation if recovered within 72 hours.

Equipment Standards:

Full-face masks with comms systems ($2,500/unit) enable real-time coordination. Teams use 80 cf steel tanks for +20% gas capacity during 45–90 min dives in 34–50°F (1–10°C) water.

5. Military & Specialized Operations

Naval Applications:

Hull mine detection dives last 120–180 mins using closed-circuit rebreathers (CCRs) with <0.5 bubble signature. Underwater cutting charges clear obstacles with ±5 cm placement accuracy.

Salvage & Recovery:

Heavy lift operations deploy 2,000–5,000 lb (900–2,270 kg) lift bags controlled by divers at 100–200 ft (30–60 m). The Costa Concordia salvage used 120+ divers logging 7,000 hours to install 30,000 tons of sponsons.

Cost-Benefit Metrics:

| Application | Operational Cost | Value Generated |

|---|---|---|

| Port Security Sweep | $8,000/day | Prevents $250M terrorism risk |

| Pipeline Repair | $120,000/job | Avoids $1.2M/day shutdown loss |

| Coral Restoration | $300/m² | Generates $170K/yr tourism/km² |

Performance Summary:

Training investment: 600 certification + 2,500 gear enables 65–500/hour professional rates

Safety record: 0.8 fatalities per 100,000 dives (2023)

Efficiency: Scientific divers collect 200–400 data points/day versus ROVs’ 50–80

SCUBA transforms human capability below the surface—from 15 reef dives to 15,000/day industrial ops—by mastering pressure physics at 1 atm increments per 10 m depth.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.